Hydrophysical Logging

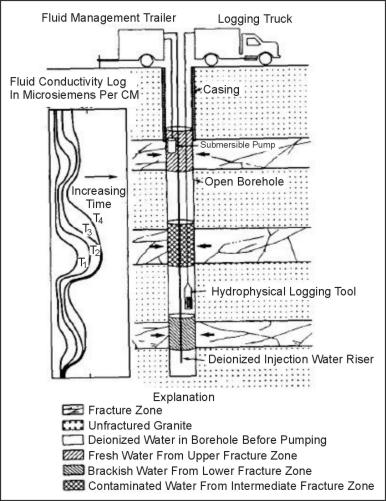

Fluid replacement and fluid-column conductivity logging, or "Hydrophysical" logging (Pedler, et al., 1990; Pedler, Head, and Williams, 1992; Tsang, Hufschmied, and Hale, 1990) involves fluid-column conductivity logging over time after the fluid column has been diluted or replaced with environmentally safe deionized water. Hydrophysical logging results are independent of borehole diameter, and the method does not require a flow concentrating diverter or packer. The logging probe involves relatively simple and readily available technology and has a small diameter allowing it to be run through an access pipe below a pump. Hydrophysical logging is used to determine flow magnitude and direction during pumping and under ambient conditions, and to identify hydraulically conductive intervals to within one well bore diameter. Figure 1 is a schematic drawing of the equipment used to replace the borehole fluid with deionized water and to subsequently run a series of fluid conductivity logs to record the inflow of formation fluids.

Figure 1. Schematic drawing of equipment used for hydrophysical logging after injection of deionized water; and time series of fluid conductivity logs, (Vernon, et al., 1993; copyright permission granted by Colog, Inc.)

Data Interpretation

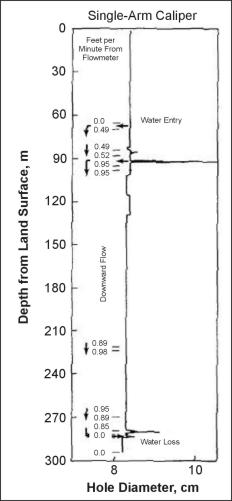

Interpretation of flowmeter logs is simple if the probe has been properly calibrated and if all the essential information on hole diameter and construction is available. Vertical flow is common in most wells that are open to more than one aquifer, and flow can be induced by pumping or injecting water. The heat-pulse flowmeter developed by Hess (1982) was used first in the field to identify fractures producing and accepting water in granitic rocks (Keys, 1984). A caliper log and data from the heat-pulse flowmeter are shown in figure 2. Data from the heat-pulse flowmeter were quite reproducible over a period of 2 weeks, even though pumping and injection tests being conducted in a well approximately 300 m from the logged well caused short-term changes. The flowmeter logs and acoustic-televiewer logs at this site enabled the Characterization of permeable fractures. In figure 3, the upper fracture zone, at a depth of approximately 90 m, and the lower zone, at a depth of approximately 290 m, both contain thin, discrete fractures that are transmitting much of the water, rather than thicker, complex fractures within each zone. Note that slightly less than half of the flow from the upper zone originates in the fracture at a depth of 94 m, although that fracture appears to be the widest on the caliper log. Similarly, the fracture that appears to be the largest in the lower zone is accepting only a small percentage of the flow. Acoustic-televiewer logs indicated that the same two fracture zones were intersected in other wells in the area and appear to constitute major aquifers. Paillet, Crowder, and Hess (1994) present a detailed description of how the heat-pulse flowmeter, in combination with acoustic-televiewer logs, can be used to acterize the hydraulic properties of fracture systems that intersect multiple drill holes.

Figure 2. Single arm caliper log on the right and data from heat pulse flowmeter showing zones of water entry and exit.

Data Interpretation

Finite Difference Modeling Software. A critical element in the application of hydrophysical logging compared to established conductive tracer technology is the development of finite difference modeling software routines to simulate the data obtained in the field. This software also permits the calculation of permeability. The method can also be expanded to measure other properties such as water temperature and pH, to determine the properties of the formation water entering the borehole. Therefore, fluid replacement logging can indicate the quality and physical properties of water entering the borehole along with the magnitude and direction of flow. In theory, there are no upper or lower limits to the magnitude of flow that can be detected. Published field studies demonstrate that the technique has achieved better low-flow resolution than that reported with other flow measurement techniques (Vernon, et al., 1993).

.

The pages found under Surface Methods and Borehole Methods are substantially based on a report produced by the United States Department of Transportation:

Wightman, W. E., Jalinoos, F., Sirles, P., and Hanna, K. (2003). "Application of Geophysical Methods to Highway Related Problems." Federal Highway Administration, Central Federal Lands Highway Division, Lakewood, CO, Publication No. FHWA-IF-04-021, September 2003. http://www.cflhd.gov/resources/agm/![]()

![[logo] US EPA](../gif/logo_epaseal.gif)