Pacific Southwest, Region 9

Serving: Arizona, California, Hawaii, Nevada, Pacific Islands, Tribal Nations

Organics: Co-Digestion Economic Analysis Tool (CoEAT)

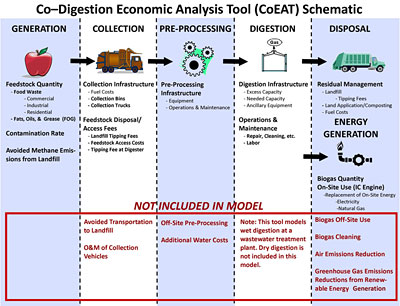

The Co-Digestion Economic Analysis Tool (CoEAT) assesses the initial economic feasibility of food waste co-digestion at wastewater treatment plants for the purpose of biogas production.

Contact: Charlotte Ely (Ely.Charlotte@epa.gov)

(415) 972-3731

Below are FAQs with detailed information on how users can adjust assumptions and costs to fit their circumstances.

Food Waste Feedstock Estimate

- Q: My community/facility has specific information on our waste stream. How do we enter that data into the tool?

- A: If you have detailed feedstock data, do not input any information except potential contamination rate (User Inputs, Cell E89) on the User Inputs Page. Enter your detailed information (tons/day) into Worksheet 1 – Feedstock Parameters, cells C28-C39.

- Q: I will not be sourcing food waste or FOG from residential areas. How do I ensure household waste is not included?

- A: Do not enter the population of the residential area being considered for food waste collection (User Inputs, Cell E31).

- Q: I will not be sourcing food waste or FOG from commercial areas. How do I ensure commercial waste is not included?

- A: If you plan solely sourcing residential food waste, only enter the population of your community (User Inputs, Cell E31) and the potential contamination rate (User Inputs, Cell E89).

- Q: I am using Option 2 under Food Waste Feedstock Estimate and have more specific information about the food waste generating establishments (i.e. number people at a school or amount of food waste from those establishments). How do I incorporate that information into the tool?

- A: Food waste generation estimates by generator category can be found in Worksheet 2 – Food Waste Feedstock Data starting on Cell B78. From this information, you can calculate the amount of food waste per establishment. After calculating these numbers, input them into Worksheet 2 – Food Waste Feedstock Data cells E57 – E68.

Existing Anaerobic Digester

- Q: What is “Effective Operating Capacity”?

- A: Percentage of anaerobic digester vessel capacity that is available for feedstock (sewage sludge and food). This capacity is determined by dividing the volume that is available for feedstock (sewage sludge and food) by its rated capacity (total volume including equipment such as mixers).

Avoided Greenhouse Gas Emissions from the Landfill

- Q: What is the difference between the WARM Model and Organic Waste Digestion Protocol calculations for methane emissions reductions from landfill?

- A: The WARM model considers methane emissions reductions from landfill over the lifetime of the material. The Climate Action Reserve’s Organic Waste Digestion Protocol uses slightly different assumptions than WARM and calculates emissions reductions for a 10-year crediting period. For more information, please visit their respective websites.

Digester Sizing and Equipment Costs

- Q: I have a one-time cost specific to my community that is not included in the tool. How can I input that into the tool?

- A: For one-time costs, you can enter them into the Ancillary Equipment Table on the User Inputs page (Cell G251).

- Q: I want to change the default size for new anaerobic digesters, how do I do that?

- A: The default can be changed by entering preferred dimensions into Worksheet 5- Digester Sizing, Row 97.

- Q: Why do the potential default costs for digesters vary so widely?

- A: The cost of digesters varies widely depending on a variety of factors including size, location, and type. In order to account for the high variability, you can use low or high cost estimation during your analysis. For more accurate information, contact your local wastewater treatment plant.

- Q: What pre-processing and ancillary equipment is required?

- A: Different equipment is required depending on a variety of factors including feedstock, existing infrastructure, and potential off-site processing. For a list of potential ancillary equipment, please see Worksheet 4 –Preproc. & Ancillary Equip.

- Q: This tool assumes that the biogas is combusted using an IC Engine with 22% efficiency. Can I change that assumption?

- A: Yes. The efficiency of your stationary engine can be changed in Worksheet 5 – Digester Sizing, Cell G71.

Overall

- Q: What components are not included as part of the tool?

-

A: The following components are not included as part of the tool (see schematic below for more information):

- Avoided transportation to landfill

- Operation & Maintenance of Collection Vehicles

- Off-site Pre-Processing

- Additional Water Costs

- Dry Digestion

- Off-site Use of Biogas

- Biogas Cleaning

- Air Emissions Reduction Technologies

- Greenhouse Gas Emissions Reductions from Renewable Energy Generation