- Energy Recovery Home

- Basic Information

- Waste Management Hierarchy

- Related Regulations

- Frequent Questions

- Additional Information

Basic Information

Highlights

Energy Generated from a Ton of Trash

A typical WTE plant generates about 550 kilowatt hours (kWh) per ton of waste. At an average price of four cents per kWh, revenues per ton of solid waste would be $20 to $30. Source – Is It Better to Burn or Bury Waste for Clean Energy Generation? (PDF) (7 pp, 289K, about PDF) ![]()

History

The first US incinerator was built in 1885 on Governors Island in New York, NY. By the mid-20th Century hundreds of incinerators were in operation in the United States but until the 1960s little was known about the environmental impacts of the water discharges and air emissions from these incinerators. When the Clean Air Act (CAA) was enacted in 1970, existing incineration facilities became subject to new standards that banned the uncontrolled burning of municipal solid waste (MSW) and placed restrictions on particulate emissions. The facilities that did not install the technology needed to meet the CAA requirements were closed.

Combustion of MSW grew in the 1980s, with more than 15 percent of all U.S. MSW being combusted by the early 1990s. The majority of the non-hazardous waste incinerators were recovering energy by this time and had installed pollution control equipment. With the newly recognized threats posed by mercury and dioxin emissions, the EPA enacted the Maximum Achievable Control Technology (MACT) regulations in the 1990s. As a result, most existing facilities had to be retrofitted with air pollution control systems or be shut down.

Economics

The upfront capital needed to build an MSW combustion plant can be a significant hurdle when building a new facility. A new plant typically requires at least $100 million upfront to finance the construction; larger plants may require double to triple that amount. The economic benefits of MSW combustion may take several years to be fully realized. Long-term contracts (generally 30 years) are often developed between the facility and municipality to secure a guaranteed waste stream. MSW Combustion facilities typically collect a tipping fee from the independent contractors that drop the waste off on a daily basis. The facilities also receive income from utilities after the electricity generated from the waste is sold to the grid. A possible third stream of revenue for the facilities comes from the sale of both ferrous (iron) and non-ferrous scrap metal collected from the post-combusted ash stream.

Combustion with Energy Recovery

Types of MSW Combustion Technologies

There are three types of technologies for the combustion of MSW.

- Mass Burn Facilities – Mass burn facilities are by far the most common types of combustion facilities in the United States. The waste used to fuel the mass burn facility may or may not be sorted before it enters the combustion chamber. Many advanced municipalities separate the waste on the front end to pull off as many recyclable products as possible. Mass burn units are designed to burn MSW in a single combustion chamber under conditions of excess air. In combustion systems, excess air must be used to promote mixing and turbulence to ensure that air can reach all parts of the waste. This is necessary because of theinconsistent nature of solid waste. Most mass-burn facilities burn MSW on a sloping, moving grate that is vibrated or otherwise moved to agitate the waste and mix it with air.

- Modular Systems – Modular Systems are designed to burn unprocessed, mixed MSW. They differ from mass burn facilities in that they are much smaller and are portable. They can be moved from site to site.

- Refuse Derived Fuel Systems – These facilities use mechanical methods to shred incoming MSW, separate out non-combustible materials, and produce a combustible mixture suitable as a fuel in a dedicated furnace or as a supplemental fuel in a conventional boiler system.

Mass Burn Process

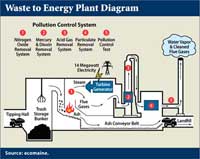

At an MSW combustion facility, MSW is unloaded from collection trucks and placed in a trash storage bunker. An overhead crane is used to sort the waste and then lift it into a combustion chamber to be burned. The heat released from burning is used to convert water to steam. The steam is then sent to a turbine generator to produce electricity. The remaining ash is collected and taken to a landfill. Particulates are captured by a high-efficiency baghouse (a filtering system). As the gas stream travels through these filters, more than 99 percent of particulate matter is removed. Captured fly ash particles fall into hoppers (funnel-shaped receptacles) and are transported by an enclosed conveyor system to the ash discharger where they are wetted to prevent dust and mixed with the bottom ash from the grate. The ash residue is then conveyed to an enclosed building where it is loaded into covered, leak-proof trucks and taken to a landfill designed to protect against groundwater contamination. Ash residue from the furnace can be processed for removal of ecyclable scrap metals. The diagram illustrates how the energy recovery process works.

Ash Generated from the MSW Combustion Process

The amount of ash generated ranges from 15-25 percent by weight of the MSW processed and from 5-15 percent of the volume of the MSW processed. Generally, MSW combustion residues consist of two types of material: fly ash and bottom ash. Fly ash refers to the fine particles that are removed from the flue gas and includes residues from other air pollution control devices, such as scrubbers. Fly ash typically amounts to 10-20 percent by weight of the total ash.

The rest of the MSW combustion ash is called bottom ash (80-90 percent by weight). The main chemical components of bottom ash are silica (sand and quartz), calcium, iron oxide, and aluminum oxide. Bottom ash usually has a moisture content of 22-62 percent by dry weight. The chemical composition of the ash varies depending on the original MSW feedstock and the combustion process. The ash that remains from the MSW combustion process is sent to landfills.

![[logo] US EPA](../gif/logo_epaseal.gif)